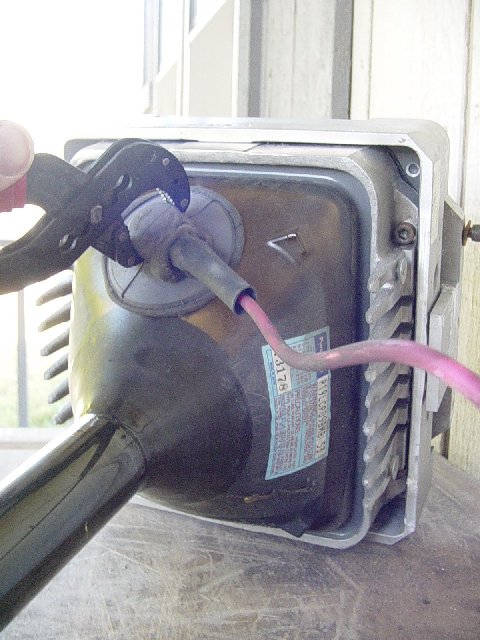

3.e Use a sharp razorblade and carefully cut around the perimeter of the high

voltage wire boot. Undercut the black silicone and try to always cut near the

glass surface. Continue cutting until all the silicone is cut loose from the

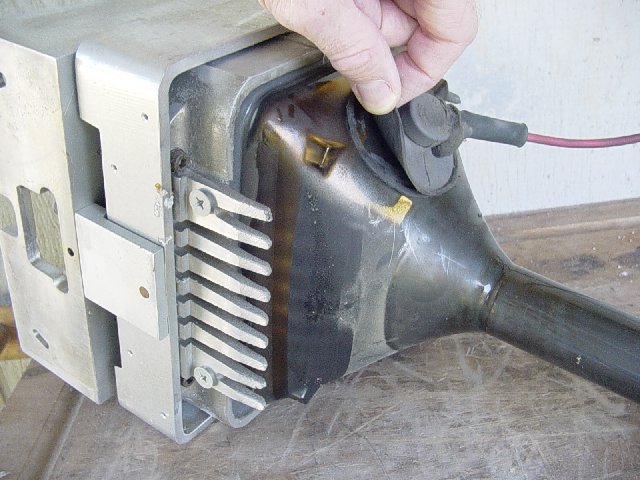

glass tube all the way around the perimeter. (Picture 3.e)

Picture 3.e.

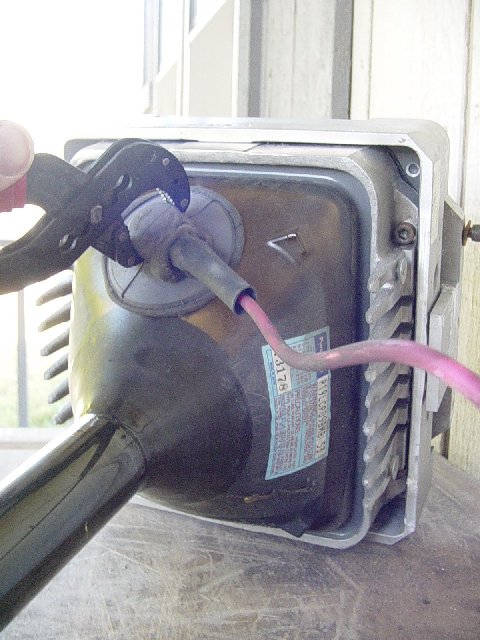

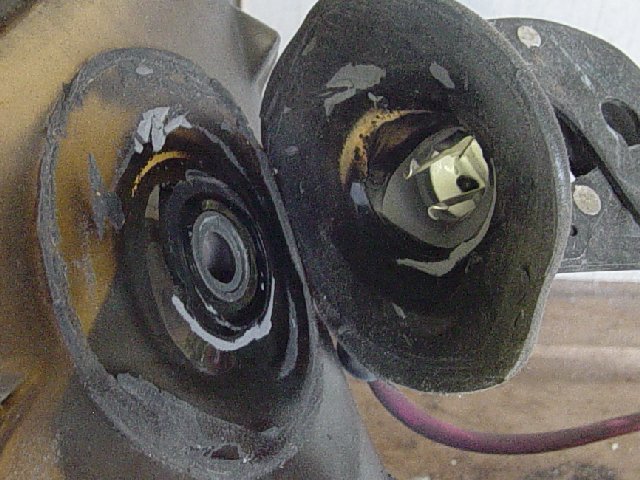

3.e.1 Use some pliers and squeeze the top of the cap to remove it. Squeeze

perpendicular (90 degrees) to the wire (Picture 3.e.1). Squeeze the cap,

maintain pressure, and remove. (Picture 3.e.2) You might have to fight the

little metal clips some (Picture 3.e.3), and a little bit of silicone that you

missed.

Picture 3.e.1.

Picture 3.e.2.

Picture 3.e.3.

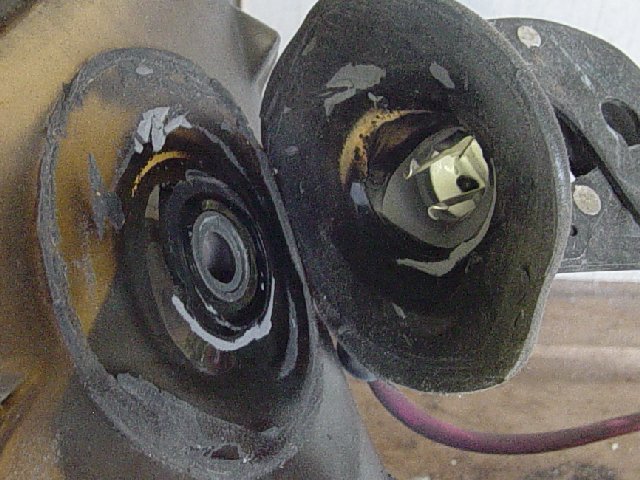

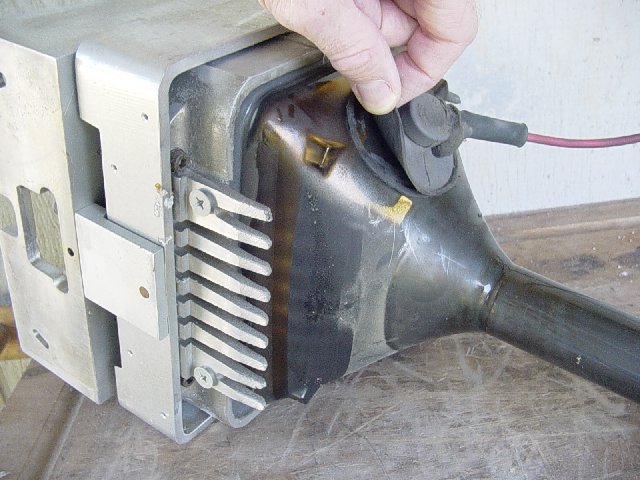

3.f This completes all the tube electronics removal. (Picture 3.f)

Picture 3.f.

4. Staking your pins:

4.a This is a good time to stake your housing pins. Tim mentions this on his

website (http://www.etechvideo.com/techtip7.htm), and now is a convenient time

to do it.

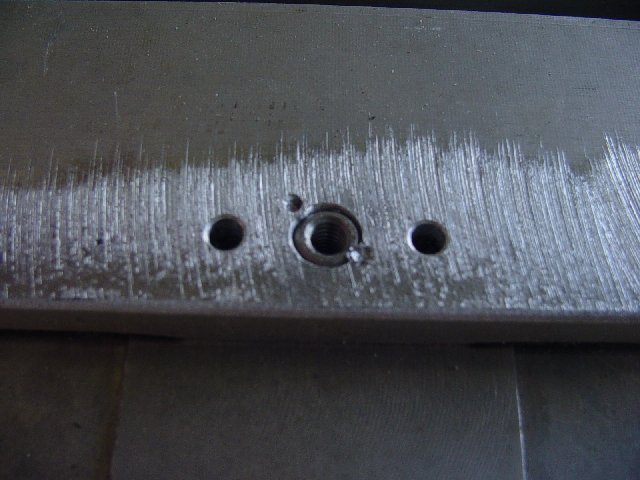

4.b The housing pins can work out easily (Picture 4.b.1), so tap the pins back

in flush (Picture 4.b.2) and then use a hammer punch and stake the housing. The

idea is to create a dimple near the pin edge. The dimple helps hold the pin in

place. (Picture 4.b.3)

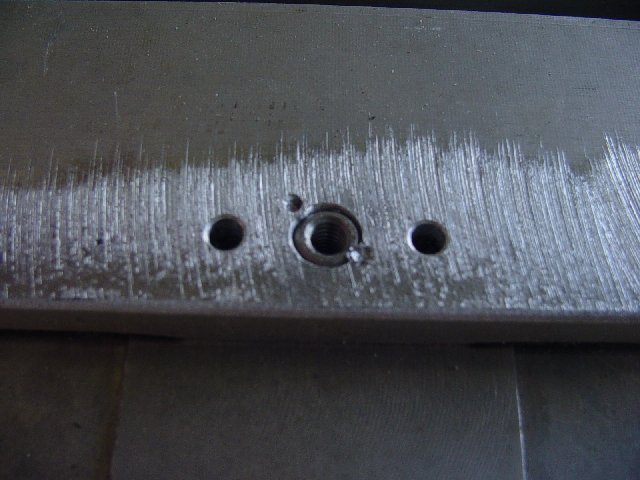

Picture 4.b.1.

Picture 4.b.2.

Picture 4.b.3.

5. Draining the Glycol:

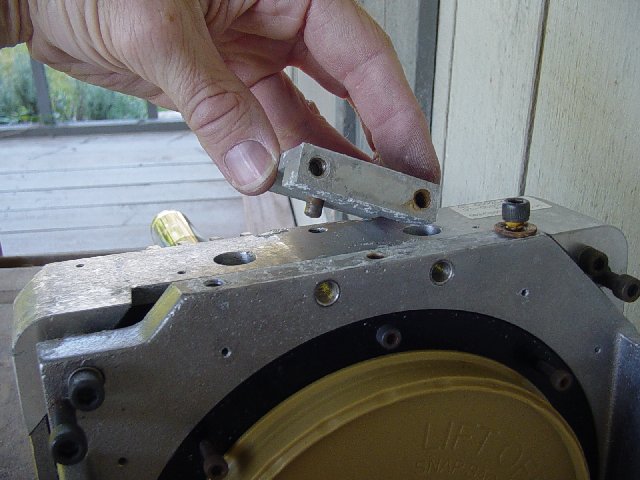

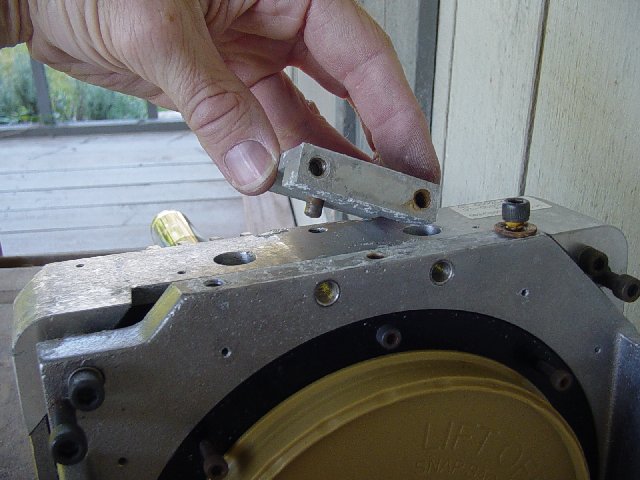

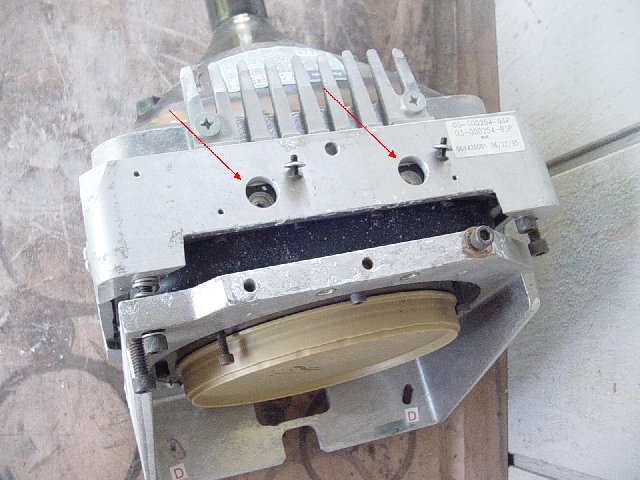

5.a Remove the upper and lower pivot plates. (Picture 5.a) This is done to help

relieve the compressive pressure that the rubber bellows is under (and hence

glycol under pressure). If the plates are not removed, there is a possibility

that some of the glycol will shoot out of the fill screws in step 5.b.

Picture 5.a.

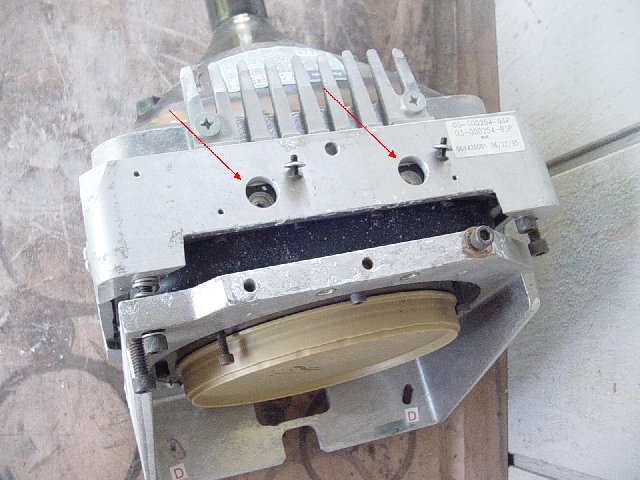

5.b Remove both glycol fill screws. (Picture 5.b)

Picture 5.b.

|