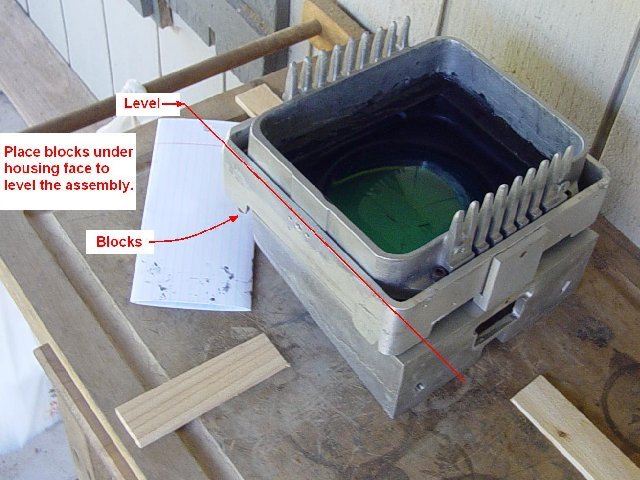

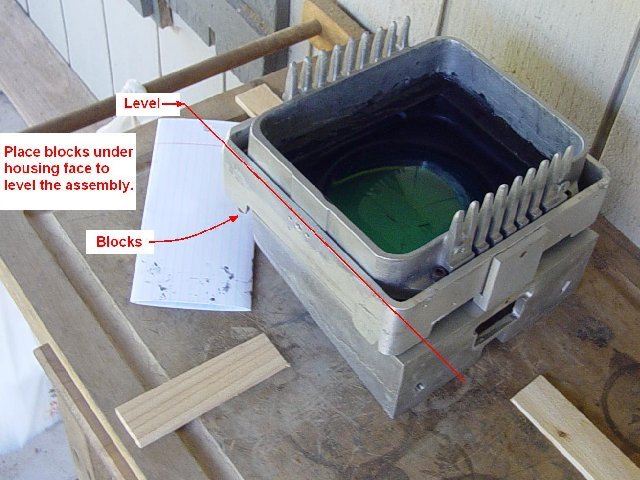

10.j Once you have a complete smooth layer of silicone on the mounting

surface, place some blocks under the housing face so that the mounting surface

is level. (Picture 10.j)

Picture 10.j.

10.k We will now be mounting the tube into the housing. It is important to

make sure the tube is centered during mounting. Any significant tube adjustment

after setting will smear the silicone on the tube face, which will reduce some

useable phosphor area. To help minimize tube adjustment, I glued two of the

shims (ref step 10.d) to the housing. A little dab of silicone on the shims will

hold it in place. (Picture 10.k)

Picture 10.k.

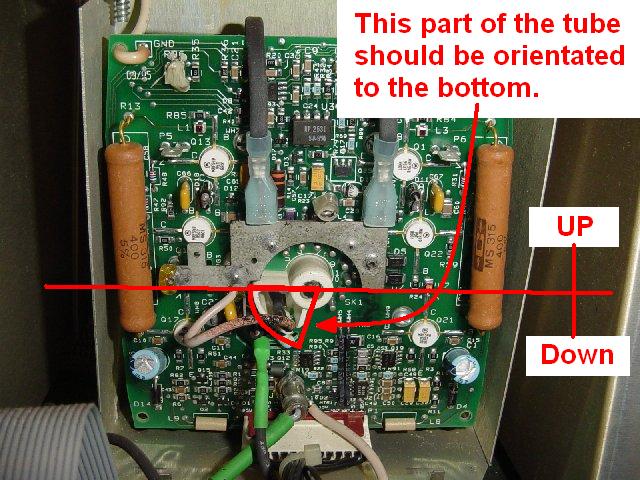

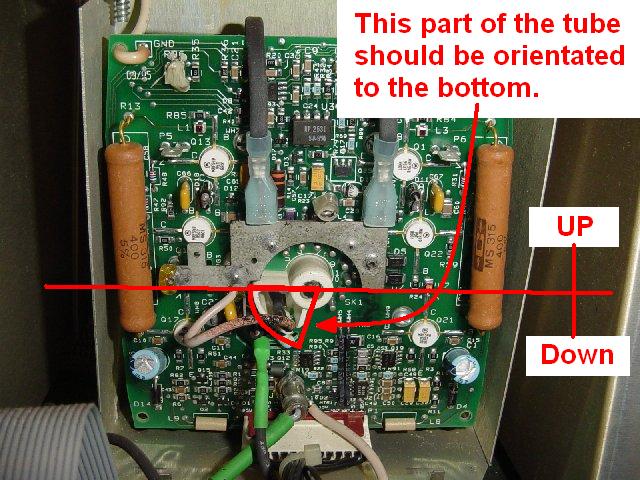

10.L Be sure not to install the tube upside-down. If you install the tube

upside down, you will not be able to connect the cables to the neckboard.

Looking at the neckboard connection, the triangular part of the connection needs

to be down – not up. (Picture 10.L)

Picture 10.L.

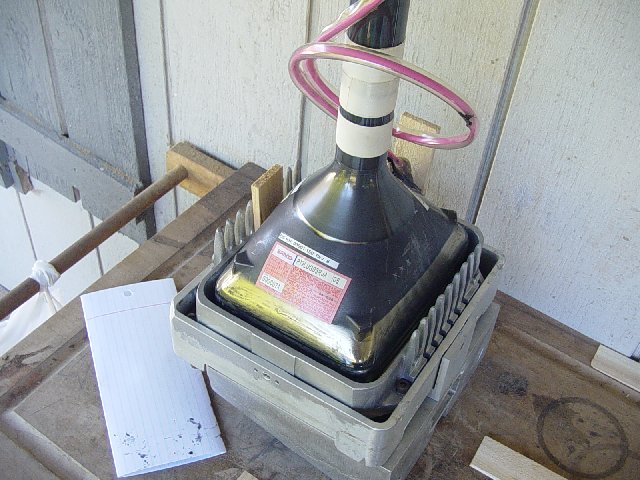

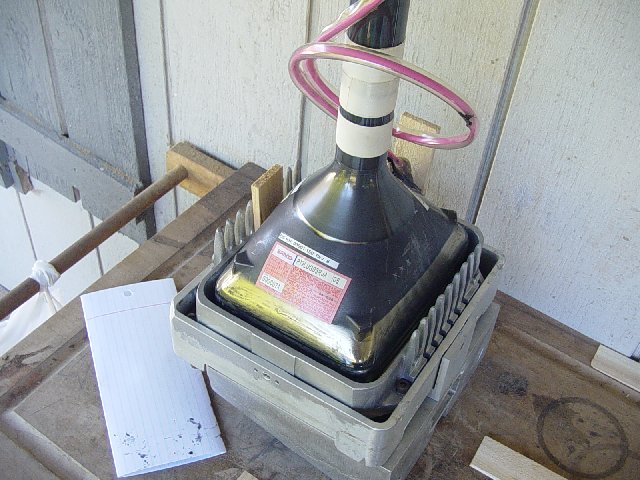

10.m Carefully set the tube down into the housing. Maintain slight pressure

from the tube against the two-glued shims to help ensure the tube is centered

when lowered into the housing. (Picture 10.m) After the tube is completely set

in the housing (and silicone) place the last two shims in place.

Picture 10.m.

10.n Lightly tap the shims down to lock/wedge the tube in place in the

housing. (Picture 10.n.1) Ensure the tube is centered in the housing. Allow the

tube silicone to cure (approx 1 day) (Picture 10.n.2). Store silicone tube to be

used later.

Picture 10.n.1.

Picture 10.n.2.

10.o After silicone has cured, remove shims, and get silicone tube ready for

continued use. Take a typical drinking straw, cut it to 4-6 inches long, and

tape the drinking straw onto end of the silicone tube nozzle. …Use plenty of

tape. (Picture 10.o)

Picture 10.o.

10.p Apply more silicone to the housing to fill the housing/tube gap. To

ensure a complete filling of the gap without air pockets, use the straw to fill

the gap starting at the bottom until the gap is full of silicone.

10.q Apply silicone to the bottom side of the high voltage wire boot and install

on tube. (If applicable)

10.r After complete, allow silicone to cure. (Few days)

11 Filling your new tubes with Glycol:

11.a After silicone is cured, remove both fill screws and fill the tube chamber

with glycol coolant. To get the glycol in the very small fill holes, I used a

(very) large syringe that I bought from a veterinary clinic (the vet cares for

large farm animals). The syringe I used was a 2oz syringe with a 14 gauge x

1.5-inch long needle. I used just under 20 oz of glycol per tube. When finished

install both fill screws. (Picture 11.a.1, Picture 11.a.2)

Note: It’s recommended to leave a little air in the glycol chamber for fluid

expansion when it heats up, (or when the glycol absorbs water from the air over

the course of a few years). As the glycol heats up and expands - it will apply

pressure on the C-element, tube, and bellows. With enough pressure, a leak or

other damage may occur. The air bubble will allow some room for expansion and

will help against any damaging pressure build-up.

Picture 11.a.1.

Picture 11.a.2.

12. Re-install electronics & reassemble housing:

12.a Re-install ground strap, scan yoke, focus yoke, flare yoke. Ensure the

appropriate yokes (R/G/B) are installed onto the appropriate tube. (Ref note in

step 3.a.) Reassemble tube housing in reverse order. Refer to Tim Martin’s

website for electronics adjustment: www.etechvideo.com

12.b If you are installing tubes other than the original P19LCP style (more

typical for 9” tubes), then make appropriate modifications to your neck boards

before installing (if necessary). Refer to Curt Palme for instructions.

| Did you find this information useful? Please consider making a

donation to help defray the cost of managing and hosting future

articles, tips, and documents. |

|

|

|

Or

purchase

from

Amazon.com

and a small percentage automatically

goes to support this site at no extra cost to you! Visit their

Blu-ray and

4K UHD

stores for sales.

Want to show off your

home theater? See our

Blu-ray Release List & Must-Have Titles. |

|

|

|

|